In an increasingly environmentally conscious world, the use of recycled materials is essential. Since its origins, LPET has focused on manufacturing 100% recycled PET sheets with the highest quality and safety standards, providing a reliable and competitive alternative for the manufacture of packaging in the different industries that we are present in.

Polyethylene Terephthalate (better known by its acronym as PET) is a linear thermoplastic polymer, with a high degree of crystallinity that belongs to the group of synthetic materials called polyesters. It is a type of plastic widely used in beverage and textile packaging.

In addition to its versatility, it is one of the most recycled plastics worldwide. Mexico recovers 56% of PET containers throughout the Americas, positioning itself as the leader in recycling plastics on a continental level. Europe has a 52% PET recycling rate, and the United States has 31%. These properties make PET a profitable, ecological, and sustainable product for packaging.

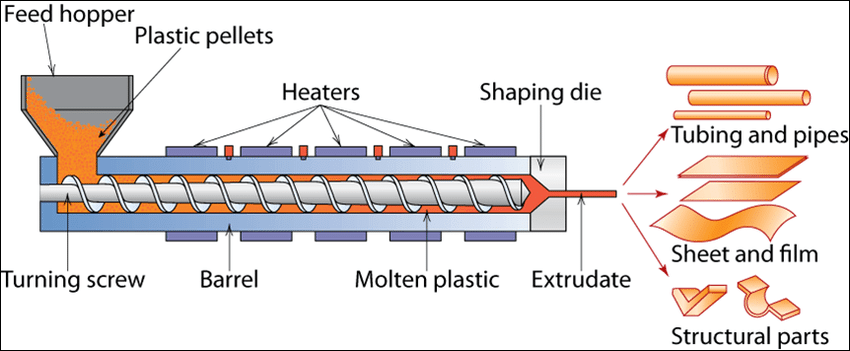

It is made by means of Extrusion. The extrusion of polymers is a mechanical industrial process where a plastic molding action is carried out, which by continuous flow with pressure and push, makes it pass through a mold in charge of giving it the desired shape. The molten polymer (or in a viscoelastic state) is forced to pass through a die, also called a head, by means of the thrust generated by the rotating action of a spindle (Archimedean screw) that rotates concentrically in a chamber at controlled temperatures called a barrel, with a millimeter separation between both elements. The polymeric material is fed through a hopper at one end of the machine and due to the pushing action, it melts. It flows and mixes in the barrel and is obtained on the other side with a pre-established geometric profile.

In a flat film extrusion line, the die is the essential piece of the system that is at the end of the barrel or head, since it gives the shape that the polymer will have in its final application. For accurate uniformity in the thickness of the film at the exit of the die, the fundamental factor is the design and the correct distribution of the temperatures along the same, as well as the adjustment of the lips where the plastic will flow and take its final form:

The flat die extrusion process offers some variants with respect to film extrusion, being the method to obtain sheets for applications such as thermoforming: blister pack, skin pack (vacuum packaging), disposable articles and sheets of various thicknesses for various uses.

The raw material for LPET to make its sheets comes from landfills where our suppliers obtain bottles and other PET packaging; this material is classified, crushed, and washed. These flakes are transformed into our food grade PET sheet with 100% recycled origin thanks to our international food safety certifications. Some properties of PET can be found in other materials, such as PVC. However, it is the unique qualities of PET that make a big difference compared to other polymers. Some of these advantages are:

Lower environmental impact: Unlike other materials, PET is one of the most recycled plastics in the world. At LPET, we have a biodegradable agent that we can include in our RPET sheets that reduces its natural biodegradation in the environment from 500 to 5 years.

Optimal for food storage: Helps keep food safe and free from contamination. LPET sheets have food safety certifications such as FSSC 22000 version 5.1 and the FDA Letter of No Objection (LNO), for holding fresh produce at room temperature and below, whose are used to manufacture thermoformed trays, containers, and packaging in these types of industries.

Durability: It is a resistant, light, and durable material that makes it a perfect packaging to contain and / or transport non-perishable products such as mechanical and electromechanical parts used in the electronics and automotive industry.

Low cost: Being of 100% recycled origin, our RPET sheet is more accessible in price.

Switching to LPET will not only bring benefits in the production of your thermoforming products, but you will also be part of a community that supports the environment and contributes to creating a more sustainable world. We invite you to be part of this change. Contact us, and receive a quote, and let’s make a more sustainable world together.

#LPETRedefiningTheFuture.