Agro

The use of PET trays, packaging and/or containers in the agricultural sector responds to the need to achieve increases in both quality and quantity in production with an impact on cost reduction, ensuring the final product with resistance and lightness of a food grade packaging, favoring its packaging, handling, and transport.

Food packing

A plastic container is required to guarantee the safety, hygiene, and health of people, which is suitable to house food products without any risk. That is why the use of PET is essential to have a low-cost option that protects and enhances the shapes, textures, and flavors of food. The use of trays, packaging and/or PET containers is ideal for those companies that have or supply raw and prepared foods services, where the food grade of our sheet meets international food safety standards, being suitable to keep at room temperature or lower.

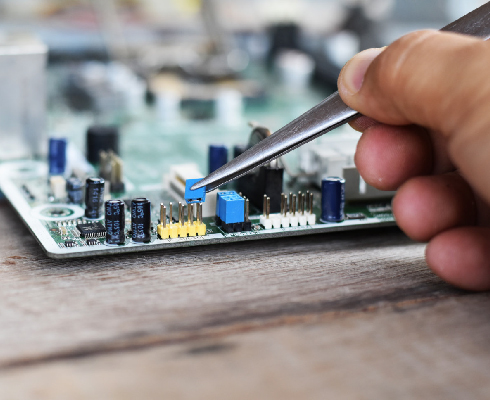

Electronic

The great versatility of plastic materials, both in design and finishes, together with the potential of the different transformation processes, has taken on a leading role in certain sectors such as electrical and electronic. In addition, the use of PET trays, packaging and / or containers with Dissipative Antistatic treatment is especially useful for transportation and packaging of electrical and electronic equipment that require to be contained in this type of packaging with electrostatic discharge (ESD) properties to avoid the damage or short circuit.

Automotive

PET is a long-lasting, resistant and high-added value material that can be used in trays and packaging for the transport of mechanical, electromechanical and electronic auto parts, in addition to helping to reduce costs and risks for auto parts manufacturing companies since its useful life is greater against other materials such as cardboard, in addition to the fact that the ESD treatment maintains the integrity of the electronic components or devices on their journey to the assembly line.

Contact us

Carretera al CUCBA 1204, Int.18, Col. San Juan de Ocotán, 45019, Jal., México.

+52 5585317699

+ 52 3339566235